Critical Barriers

Facing the Manufacturing Sector

Lack of End-to-End Supply Chain Visibility

Difficulty in real-time inventory tracking and demand forecasting leads to production disruptions and operational waste due to unsynchronized information.

Siloed and Disconnected Operational Infrastructure

ERP and Manufacturing Execution Systems (MES) often operate independently. This lack of integration with the Front Office delays decision-making and hinders business agility.

Pressure to Pivot toward Service-Oriented Models

Transitioning from selling pure hardware to a Product-as-a-Service model is a major challenge, requiring sophisticated product lifecycle management and specialized customer care.

Optimizing Performance and Quality Standards

High barriers to entry in leveraging AI/ML to analyze IoT Data from machinery for predictive maintenance and ensuring international-standard product quality.

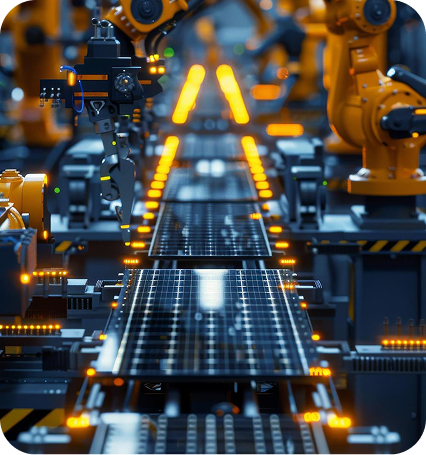

Trends Reshaping the Future of Manufacturing

As the industry shifts toward Industry 4.0, Gimasys focuses on four strategic pillars to ensure holistic visibility and competitive performance:

- Cloud-Native Smart Factories: Migrating core manufacturing operations to the Cloud to enable real-time IoT data integration and seamless scalability.

- End-to-End Supply Chain Synchronization: Deploying modern ERP/SCM solutions to unify procurement, production, and distribution, fostering an agile and resilient supply chain.

- Front-to-Back Office Integration: Leveraging CRM platforms to bridge the gap between market demand and production data, supporting Product-as-a-Service models and personalized after-sales support.

- Intelligent Operations: Applying AI/ML and Big Data to factory floor analytics. Focus areas include Predictive Maintenance, automated quality control, and real-time Overall Equipment Effectiveness (OEE) optimization.

Gimasys Competencies in Manufacturing Sector

Deep Industry Domain Expertise

With nearly 20 years of experience, Gimasys possesses a profound understanding of manufacturing operations. We deliver superior advisory and implementation services focused on supply chain and production efficiency.

Comprehensive Digital Solutions Ecosystem

We provide an integrated ecosystem (ERP, SCM, CRM, Cloud) that connects the Front Office to the Back Office, maximizing operational visibility across the entire value chain.

Bespoke Solution Architecture

Our solutions are custom-engineered for the manufacturing floor, not only automating processes but also optimizing resource allocation and modernizing core infrastructure.

Pioneering Industry 4.0 Innovations

Gimasys leads in applying AI/ML and IoT Data to industrial operations, empowering factories to achieve predictive maintenance, OEE optimization, and superior product quality.

Discrete

Process

Outsourcing

Manufacturing Models

We Empower

Gimasys provides integrated digital solutions for diverse manufacturing environments: Discrete Manufacturing, Process Manufacturing, and Outsourcing.

With deep expertise in each specific model, we help enterprises standardize workflows, optimize resources, and elevate performance. Our goal is to enhance predictive capabilities and quality control, creating a sustainable competitive advantage in the Industry 4.0 era.

Our Trusted Clients

Contact us today to learn more about Gimasys' specialized solutions for the Manufacturing sector